Products

Contact Us

Tel:+86-13345113241(Flora Li)

WeChat:+86-133-4511-3241

WhatsApp:+86-133-4511-3241

Email:sales@clgreenhousefilm.com

Email:liflora426@gmail.com

Factory Address: Zhuliang Plastics Industrial Park, Gaoliu Town, Qingzhou City, Shandong Province

Jinan Foreign Trade Sales Address: Unit 2, Building 7, Shanggan Xintiandi, Industrial South Road, Jinan City

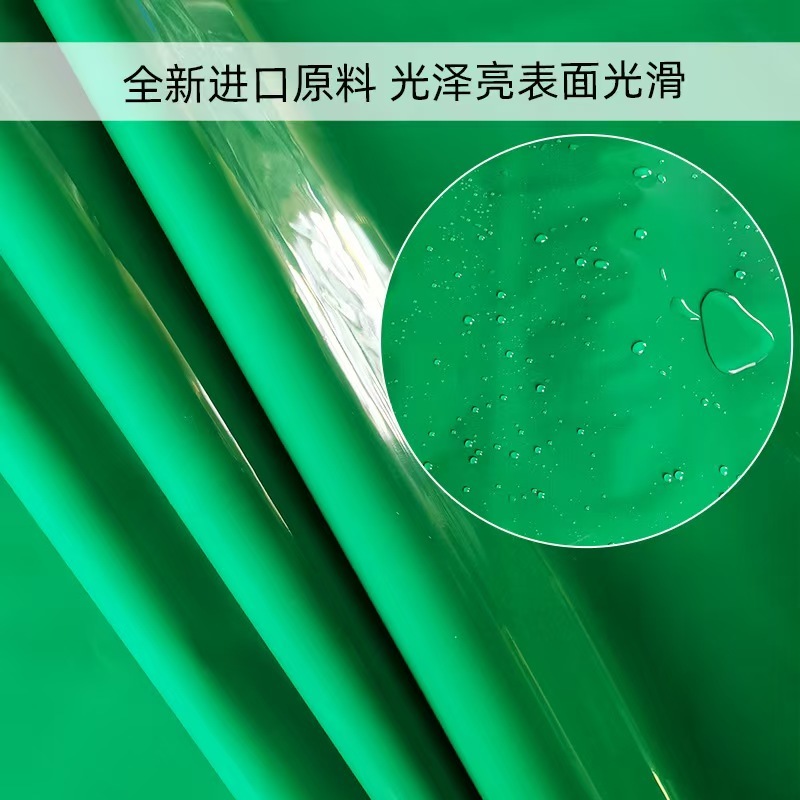

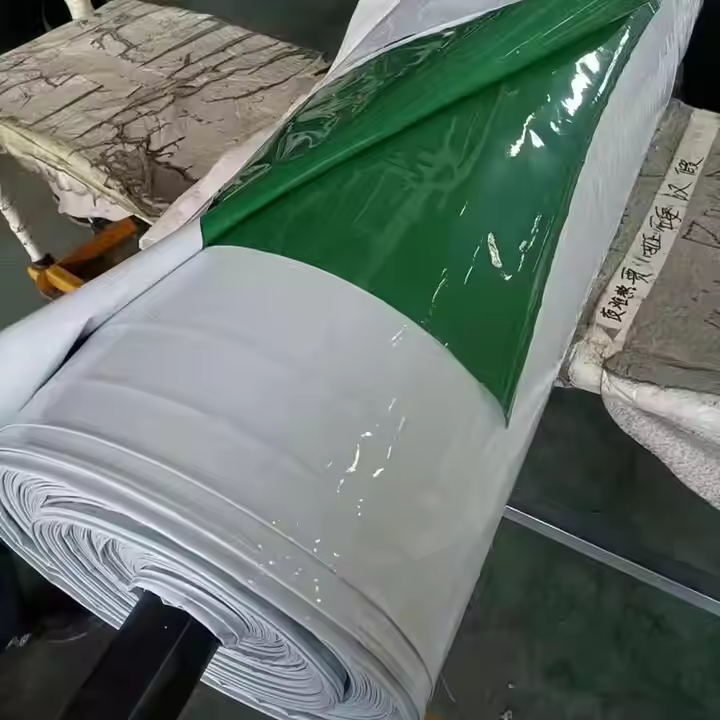

Green and white film

Green and white film (12/13 mil or more) Uses: Special film for edible mushroom greenhouses Features: 8%-20% scattered light, cooling/heat insulation/long lifespan

Details Description

Basic Structure:

Outer layer (green side): Typically made of polyethylene (PE) with added green masterbatch and anti-aging additives, mainly used for shading and reflecting part of the light.

Inner layer (white side): Mostly white PE film, added with light reflectors or diffused reflection materials to enhance light reflection and heat preservation in the greenhouse.

Thickness: Common specifications are 0.12–0.15 mm. Thickened types (e.g., over 0.2 mm, with a service life of 3–5 years) can be selected based on durability requirements.

Functional Additives: Some products include additives like UV resistance, dust prevention, and drip resistance (to prevent condensation), enhancing comprehensive performance.

II. Core Functions and Application Scenarios of Green-White Film

1.Sunshade and Cooling – Core Role of the Green Side

2.Principle: The green outer layer reflects part of the visible light and infrared rays (especially the green light band), reducing solar radiation entering the greenhouse and mitigating the impact of high summer temperatures on farmed animals.

Application Scenarios:

High-temperature regions in summer: For example, pig farms and chicken coops in southern China, it can reduce the greenhouse temperature by 3–5°C, alleviating heat stress in livestock (which can lead to decreased feed intake, slow growth, or even disease).

Aquaculture greenhouses: Such as shrimp ponds and fry greenhouses, it controls water light intensity, inhibits excessive algae growth (e.g., blue-green algae), and avoids direct (strong light) affecting aquatic animal growth.

3.Light Reflection and Heat Preservation – Core Role of the White Side

4.Principle: The white inner layer has high reflectivity, reflecting light in the greenhouse (especially scattered light) back to the ground to improve light uniformity. Meanwhile, the white material blocks long-wave radiation (heat), reducing nighttime heat loss.

Application Scenarios:

Winter heat preservation: For example, livestock sheds in northern China, it reflects light during the day to increase greenhouse brightness and slows down temperature drop at night, reducing the day-night temperature difference.

High-light aquaculture scenarios: Such as laying hen houses (light affects egg production rate) and mutton sheep fattening sheds (promoting feeding and activity), the white side can increase light intensity in the greenhouse by 10%–20%.

5.Other Auxiliary Functions

6.Dust Resistance and Aging Resistance: The green outer layer usually has a dust-proof coating to reduce dust adhesion (especially in outdoor environments) and maintain light transmittance. Anti-aging additives extend the film's service life (common type) lasts about 2 years, while thickened anti-aging types can last over 5 years).

Drip and Anti-Fogging: Some green-white films have inner-layer drip agents, causing condensed water to slide along the film surface instead of forming fog drops, reducing greenhouse humidity (high humidity can cause respiratory diseases) and preventing water droplets from directly falling on animals or feed.

III. Applications of Green-White Film in Different Aquaculture Scenarios

1.Livestock and Poultry Farming

2.Pig Sheds:

In summer, use the green side outward to reduce pig shed temperature and minimize heatstroke risks. In winter, flip it (white side outward) for better heat preservation (with ventilation management to avoid high humidity).

Suitable for open or semi-open pig greenhouses, replacing the traditional double-layer structure of sunshade net + plastic film to simplify construction costs.

Chicken Coops:

Laying hen houses prefer the white side outward to enhance light for egg production; broiler houses focus on summer shading with the green side outward to reduce energy consumption.

Can be used with ventilation windows to achieve dual effects of "sunshade + ventilation".

Cattle and Sheep Sheds:

Used for outdoor fattening or milking parlor shading, the green side reduces stress from direct 强光 (strong light) on animals while maintaining ventilation and light in the shed.

3.Aquaculture

4.Fish/Shrimp Pond Greenhouses:

In spring, use the white side outward to increase greenhouse temperature and accelerate seedling growth. In summer, switch to the green side outward to maintain water temperature within the optimal range of 25–30°C.

Reduces explosive algae growth (e.g., moss, blue-green algae) caused by direct sunlight, maintaining water quality stability.

Nursery Pond Covering:

The white side reflects light to evenly distribute light in the pond, preventing seedlings from gathering in strong or weak light areas and improving survival rates.

5.Specialty Farming

6.Bee Farming:

In winter, cover beehive greenhouses with the white side outward to reflect sunlight and prevent excessive greenhouse heating, avoiding bees from emerging too early and freezing to death. In summer, use the green side for shading to keep the hive cool.

Earthworm/Insect Farming:

The green side provides shade (earthworms prefer dark environments), and the white side reflects heat to prevent high temperatures from suffocating insects.

IV. Advantages and Disadvantages of Green-White Film

|

Advantages |

Disadvantages |

|

1. Dual-sided functions for year-round use |

1. Requires regular flipping (in some scenarios) |

|

2. Balanced sunshade and heat preservation effects |

2. Light transmittance is lower than transparent film (about 60%–80%) |

|

3. Lower cost than composite functional films |

3. Weaker wind resistance (needs to be reinforced with a framework) |

|

4. Easy to install, replacing double-layer coverage |

4. The white side easily adsorbs dust and requires regular cleaning |

V. Selection and Usage Recommendations for Green-White Film

1.Selection Key Points

2.Choose by regional climate:

Southern high-temperature and rainy areas: Prioritize thickened anti-aging + drip-type green-white film, mainly with the green side outward, for longer life and anti-fogging.

Northern areas with cold winters and hot summers: Choose double-sided usable types, using the white side outward for winter heat preservation and the green side outward for summer cooling.

Choose by farming variety needs:

Light-sensitive animals (e.g., laying hens, breeding pigs): Focus on the white side's light reflection performance, requiring film transmittance ≥70%.

Aquaculture: Prioritize dust-proof green-white film to reduce uncontrolled algae growth due to decreased film transmittance.

|

Green and white film |

|

|

|

|

Green light film, blue light film

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

Agricultural Technology

Sorry, the content is being organized, please browse other information first!

FAQ

Q

Are you a manufacturer?

A

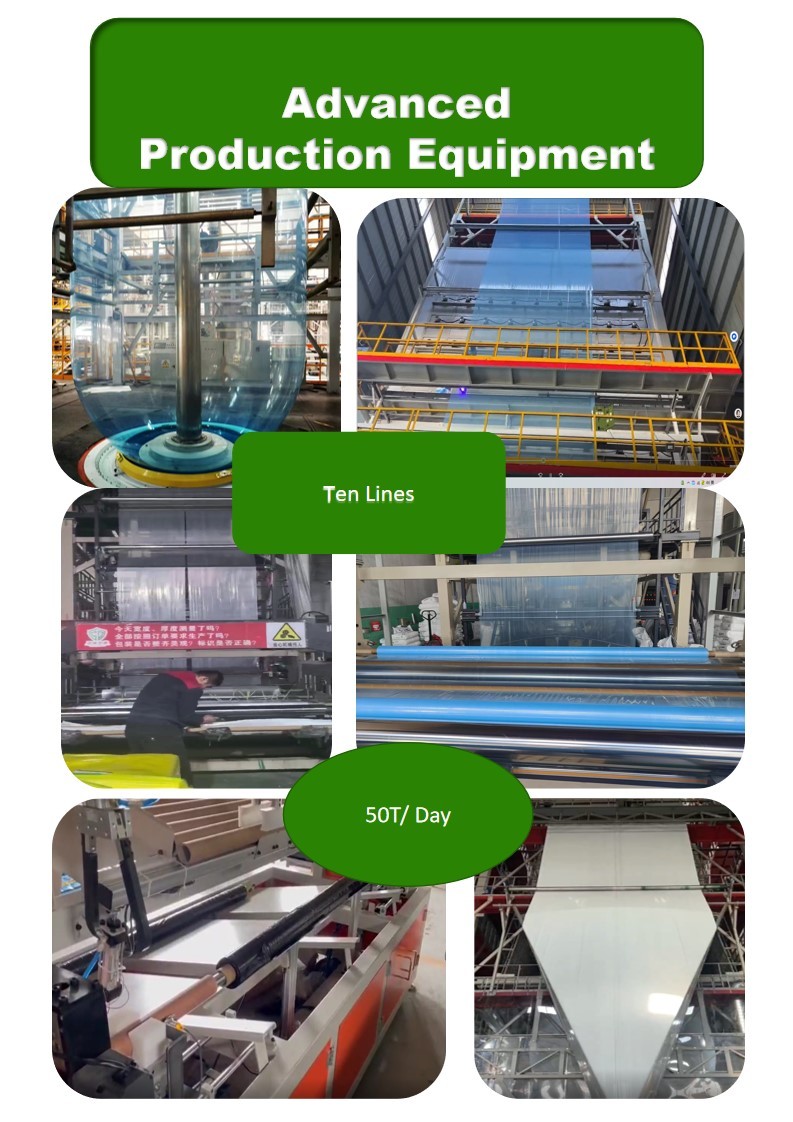

Yes, we are a agricultural film manufacturer in China, covering an area of 7,000 square meters with a daily output of 50 tons.

Q

What information should I provide to get an accurate quotation?

A

Option 1: Dimensions, thickness, width, and length and specification;

Option 2: Functional requirements, such as anti-fog, anti-drip, light conversion, diffused light, etc.;

Option 3: What plants are the greenhouses used for?

Option 4: In which country or region will it be used? Please provide a detailed description of the climate conditions at the site of use, including temperature, precipitation, etc?

Option 5: The service life (lifespan) you require for the product.

Q

Can your products be used in areas with strong UV radiation?

A

Yes, our products are very popular in the Xinjiang market of China, where there are 13 hours of sunlight during the day.

Q

What is your production capacity?

A

We produce 50 tons per day, approximately 1,100 to 1,500 tons per month.

Q

Are you willing to provide samples?

A

We provide samples for free, but the customer needs to pay the express delivery fee.

Q

Do you inspect the finished products?

A

Yes, the company has professional testing instruments and a testing department. Quality inspection is carried out for each production step and the finished products before delivery.

Q

Can your products be used in areas with frequent acid rain?

A

Yes, our products can also be well applied in acid rain areas, such as Yunnan, Sichuan, Guizhou, etc.

Q

What is your delivery time?

A

Our delivery time is about 10 to 20 days.

Q

What is your minimum order quantity (MOQ)?

A

Our minimum order quantity is 1 ton.