Products

Contact Us

Tel:+86-13345113241(Flora Li)

WeChat:+86-133-4511-3241

WhatsApp:+86-133-4511-3241

Email:sales@clgreenhousefilm.com

Email:liflora426@gmail.com

Factory Address: Zhuliang Plastics Industrial Park, Gaoliu Town, Qingzhou City, Shandong Province

Jinan Foreign Trade Sales Address: Unit 2, Building 7, Shanggan Xintiandi, Industrial South Road, Jinan City

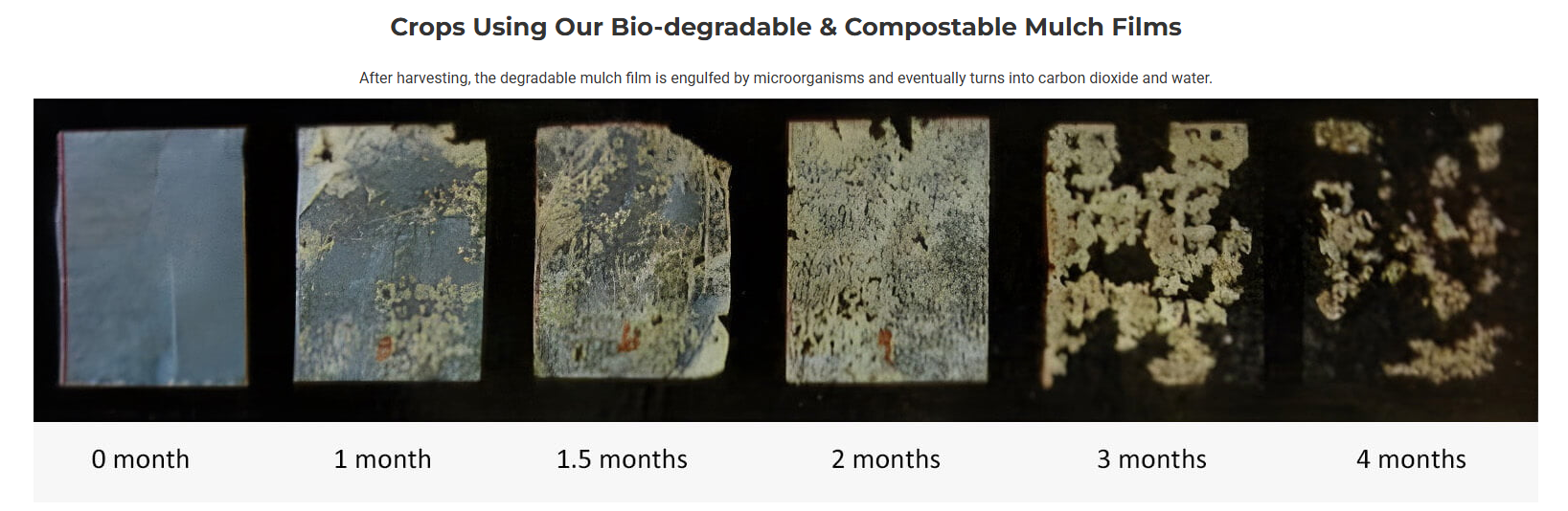

Fully biodegradable mulch film

Keywords:

Details Description

Biodegradable Mulch Film: Revolutionizing Sustainable Agriculture

Introduction

In the dynamic landscape of modern agriculture, biodegradable mulch film has emerged as a game - changing innovation. As the global community becomes increasingly conscious of environmental conservation, this eco - friendly alternative to traditional plastic mulch is rapidly gaining traction.

What is Biodegradable Mulch Film?

Biodegradable mulch film is made from materials that can be broken down naturally by microorganisms, such as bacteria, fungi, and actinomycetes, in the soil environment. These materials include biopolymers like polylactic acid (PLA), polyhydroxyalkanoates (PHA), polycaprolactone (PCL), as well as blends of these with other biodegradable components. Some biodegradable mulches also incorporate starch - based materials or cellulose derivatives.

Biodegradable Mulch Film Core Information Table

|

Category |

Details |

|

Product Definition |

Agricultural cover film made from biobased materials (e.g., polylactic acid [PLA], polyhydroxyalkanoates [PHA], starch composites) that decomposes naturally via microbial action into CO₂, water, and humus, replacing traditional polyethylene (PE) mulch. |

|

Width |

≥0.5m(customization) |

|

Thickness |

≥0.01mm (customization) |

|

Length |

(customization) |

|

Key Materials |

Biopolymers: PLA (derived from corn/sugarcane), PCL (polycaprolactone), PBAT (polybutyrate adipate terephthalate) |

|

Primary Benefits |

Environmental Sustainability: Eliminates "white pollution"; improves soil organic matter when degraded (e.g., Naturerecycle mulch converts to humus when plowed under). |

|

Application Scenarios |

Cash Crops: Vegetables (tomatoes, cucumbers, strawberries), fruits (grapes, watermelons), industrial crops (cotton, tobacco). |

|

Degradation Mechanism |

Microbial Decomposition: Soil bacteria and fungi break down polymer chains via enzymatic action. |

|

Market Trends |

Policy Drivers: China’s Agricultural Film Management Measures aims for 70% biodegradable mulch use by 2025; EU Plastic Strategy restricts traditional mulch. |

|

Comparison to Traditional Mulch |

Insert comparative points here, e.g., durability, cost, environmental impact |

|

Challenges & Solutions |

Challenges: |

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

Agricultural Technology

Sorry, the content is being organized, please browse other information first!

FAQ

Q

Are you a manufacturer?

A

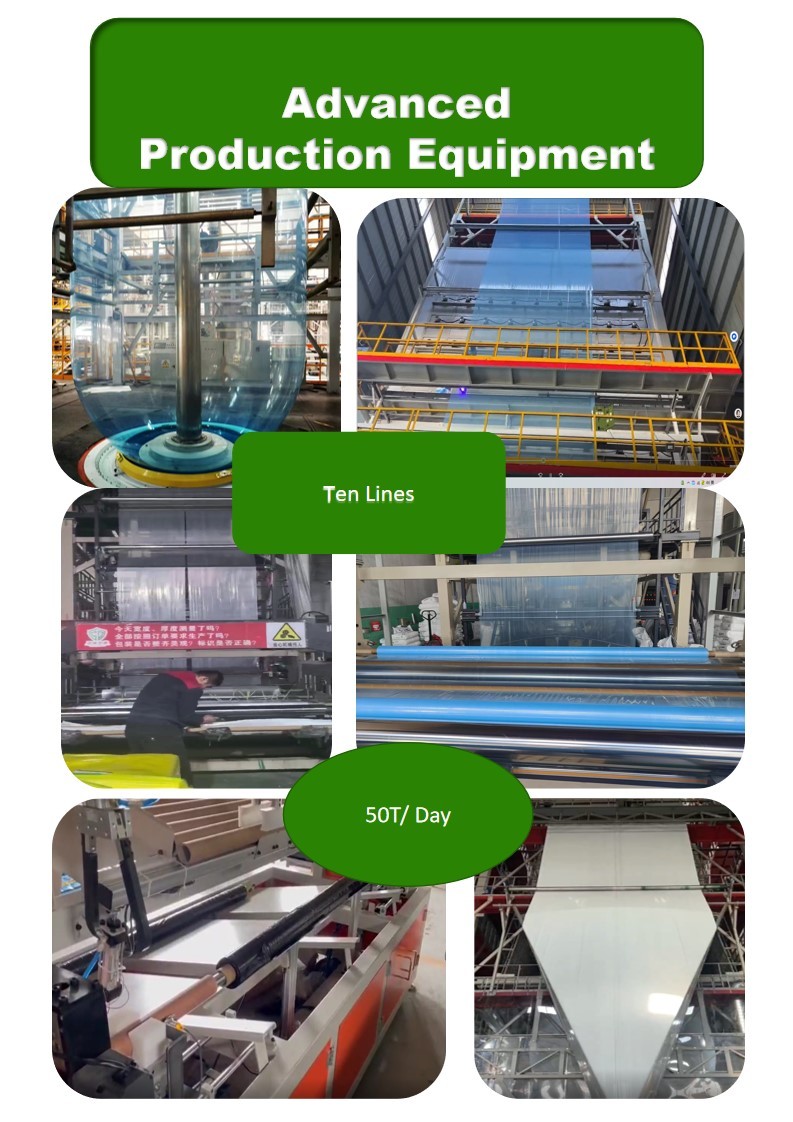

Yes, we are a agricultural film manufacturer in China, covering an area of 7,000 square meters with a daily output of 50 tons.

Q

What information should I provide to get an accurate quotation?

A

Option 1: Dimensions, thickness, width, and length and specification;

Option 2: Functional requirements, such as anti-fog, anti-drip, light conversion, diffused light, etc.;

Option 3: What plants are the greenhouses used for?

Option 4: In which country or region will it be used? Please provide a detailed description of the climate conditions at the site of use, including temperature, precipitation, etc?

Option 5: The service life (lifespan) you require for the product.

Q

Can your products be used in areas with strong UV radiation?

A

Yes, our products are very popular in the Xinjiang market of China, where there are 13 hours of sunlight during the day.

Q

What is your production capacity?

A

We produce 50 tons per day, approximately 1,100 to 1,500 tons per month.

Q

Are you willing to provide samples?

A

We provide samples for free, but the customer needs to pay the express delivery fee.

Q

Do you inspect the finished products?

A

Yes, the company has professional testing instruments and a testing department. Quality inspection is carried out for each production step and the finished products before delivery.

Q

Can your products be used in areas with frequent acid rain?

A

Yes, our products can also be well applied in acid rain areas, such as Yunnan, Sichuan, Guizhou, etc.

Q

What is your delivery time?

A

Our delivery time is about 10 to 20 days.

Q

What is your minimum order quantity (MOQ)?

A

Our minimum order quantity is 1 ton.